Water & Oil Leak Detection System (LDS)

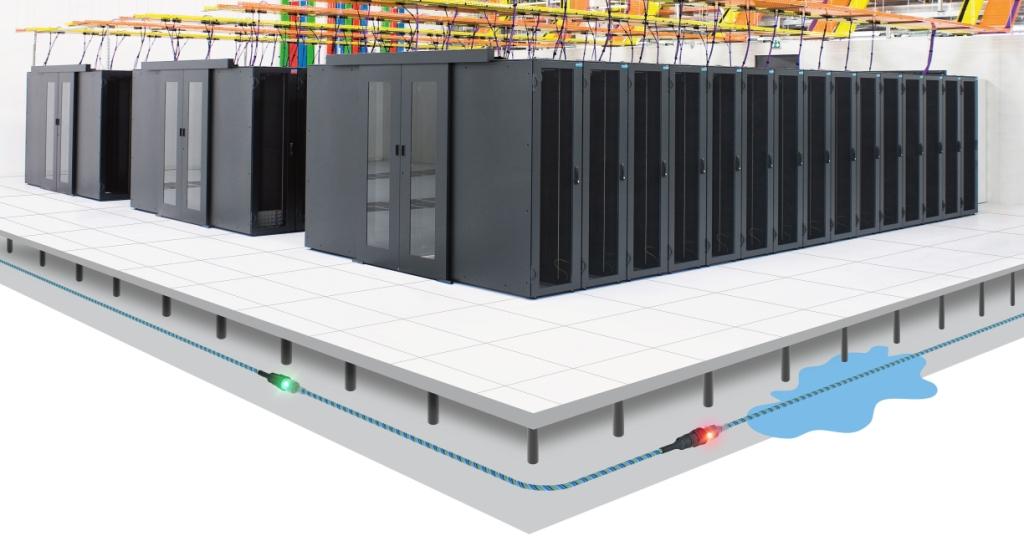

Water leak detection systems are essential for safeguarding sensitive IT equipment in server rooms and data centers from potential water damage. These advanced systems utilize a variety of sensors and technologies to quickly identify and locate water leaks, enabling prompt remediation before significant damage occurs.

State-Of-The-Art Water Leak And Oil Leak Detection Systems

At Data Build Technologies, we offer industry-leading solutions for leak detection, including state-of-the-art water leak and oil leak detection systems. Our technology is designed to provide real-time monitoring and alerts, ensuring that your critical infrastructure remains protected and operational.

Protect Critical IT Infrastructure

By incorporating a comprehensive water leak detection system designed for the unique challenges of server rooms and data centers, facility managers can protect critical IT infrastructure and ensure business continuity.

Benefits of a Comprehensive Leak Detection System

- Early leak detection: These systems can identify leaks at the earliest stages, minimizing water damage and downtime.

- Localized leak identification: Many systems can pinpoint the exact location of a leak, streamlining repair efforts.

- Compatibility with BMS: Integration with building management systems allows for centralized monitoring and control.

- Reduced risk of data loss: Preventing water damage to servers and IT equipment helps avoid costly data loss and downtime.

- Compliance with industry standards: Leak detection systems are often required to meet standards set by organizations like BICSI and NFPA

Key Components of a Server Room Water Leak Detection System

Liquid Leak Detection System essential consists of the following components.

- Ceiling-mounted leak detection sensors: These low-profile sensors are installed above drop ceilings to detect water from leaks in pipes or HVAC systems before it can drip through the ceiling tiles.

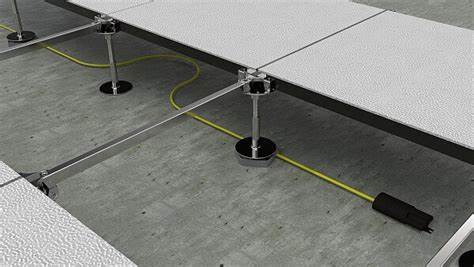

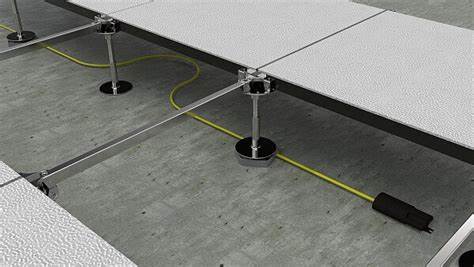

- Raised floor leak detection cables: Sensor cables are placed under raised flooring to monitor for water accumulation and alert the system to leaks from pipes, CRAC units, or other sources.

- Point sensors: Spot detectors are positioned in areas prone to leaks, such as under CRAC units or near water-carrying pipes, to provide localized monitoring.

- Control panel: The central control unit processes data from the various sensors, analyzes the information, and triggers alarms or notifications when a leak is detected.

- Notification system: Alarms, emails, text messages, or integration with building management systems (BMS) are used to alert personnel of a leak, allowing for a rapid response.

Read More About Our Products

Hot And Cold Aisle Containment For Data Center Cooling

Aisle Containment System in Data Center Aisle containment is a data center cooling strategy that separates the hot and cold airflows, creating isolated hot and cold aisles. This improves cooling efficiency and reduces…

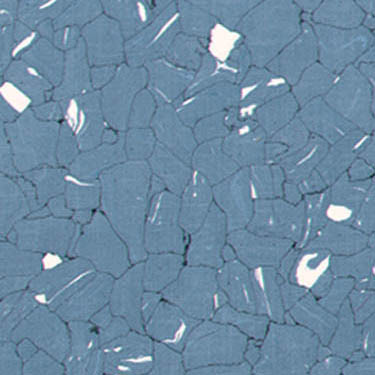

Various Raised Floor Finishes

From Data Build Technologies PVC Finish (Conductive & Static Dissipative) PVC conductive or static dissipative floor coverings mitigate the influence of electrostatic charges in sensitive work environments. Electrostatic discharge can cause significant damage…